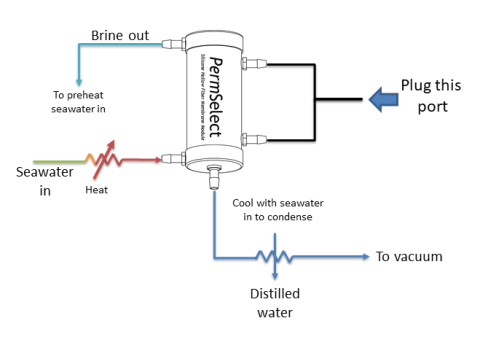

Membrane distillation (MD) is an emerging technology for separations that are traditionally accomplished via conventional distillation or reverse osmosis. As applied to water desalination, MD involves the transport of water vapor from a saline solution through the membrane. PDMS (Silicone) has a high permeability to water vapor thereby facilitating the transport of water vapor across the membrane while rejecting the salt and other solutes. Since liquid does not penetrate the hydrophobic membrane, dissolved ions are completely rejected by the membrane. MD has a number of potential advantages over conventional desalination including low temperature and pressure operation, reduced membrane strength requirements, compact size, and 100% rejection of non-volatiles.

MD could be used effectively in the Arabian Gulf States to desalinate the brines from existing thermal desalination facilities. This can leverage the latent heat of the brines while harnessing low-grade waste heat from power plants or other industrial facilities, to lower the environmental impact from discharging warmer streams into the sea. The capacity of an existing desalination facility may also be increased without incurring new capital and operating costs associated with seawater intake infrastructure and pretreatment facilities. The end result would be an overall higher product water recovery rate from the existing desalination facility.

Much research has been conducted with micro porous hydrophobic membranes or composite membranes composed of a porous substrate skinned with a thin PDMS layer. Results suggest that dense PDMS hollow fiber contactors would be ideal for membrane distillation to be economically competitive:

Sweeping Gas Membrane Desalination Using Commercial Hydrophobic Hollow Fiber Membranes SAND 2002-0138, Sandia National Laboratories Lindsey R. Evans and James E. Miller

Abstract Water shortages affect 88 developing countries that are home to half of the world’s population. In these places, 80-90% of all diseases and 30% of all deaths result from poor water quality. Furthermore, over the next 25 years, the number of people affected by severe water shortages is expected to increase fourfold. Low cost methods of purifying freshwater, and desalting seawater are required to contend with this destabilizing trend.

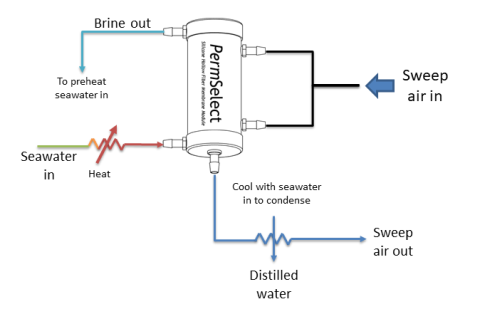

Membrane distillation (MD) is an emerging technology for separations that are traditionally accomplished via conventional distillation or reverse osmosis. As applied to desalination, MD involves the transport of water vapor from a saline solution through the pores of a hydrophobic membrane. In sweeping gas MD, a flowing gas stream is used to flush the water vapor from the permeate side of the membrane, thereby maintaining the vapor pressure gradient necessary for mass transfer. Since liquid does not penetrate the hydrophobic membrane, dissolved ions are completely rejected by the membrane. MD has a number of potential advantages over conventional desalination including low temperature and pressure operation, reduced membrane strength requirements, compact size, and 100% rejection of non-volatiles.

The present work evaluated the suitability of commercially available technology for sweeping gas membrane desalination. Evaluations were conducted with Celgard Liqui-Cel® Extra-Flow 2.5X8 membrane contactors with X-30 and X-40 hydrophobic hollow fiber membranes. Our results show that sweeping gas membrane desalination systems are capable of producing low total dissolved solids (TDS) water, typically 10 ppm or less, from seawater, using low grade heat. However, there are several barriers that currently prevent sweeping gas MD from being a viable desalination technology. The primary problem is that large air flows are required to achieve significant water yields, and the costs associated with transporting this air are prohibitive. To overcome this barrier, at least two improvements are required. First, new and different contactor geometries are necessary to achieve efficient contact with an extremely low pressure drop. Second, the temperature limits of the membranes must be increased. In the absence of these improvements, sweeping gas MD will not be economically competitive. However, the membranes may still find use in hydrid desalination systems.