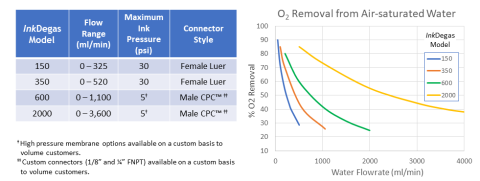

InkDegasTM Silicone Membrane Degassers Specifications and Performance Data

Dissolved gas and microbubbles in ink can significantly affect the speed and quality of printing. By interrupting droplet formation or pressurization at the ink head, dissolved gases can lead to formation of bubbles and improper jetting at the time of ink ejection. Beyond poor image quality, nozzle dropouts can cause expensive shutdown of the equipment, and the need for more frequent cleaning.

PermSelect's InkDegas silicone membrane degassers are ideal for degassing and de-bubbling compatible inks and are an excellent replacement for Pall's UltiFuzorTM (UDM-21110, UDM-41110, UDM-61110, Mimaki degassing module M801432)** Océ Arizona 02-057 / Membrana Degas Module, DIC EF-G2 degasser and Membrana's SuperPhobic© membrane contactors*.

Our InkDegas silicone membrane degassing modules are in effect a hollow fiber membrane contactor designed for efficient removal of dissolved gases from ink jet inks on-board ink jet printing systems. The ink inlet and outlet and both vacuum ports have standard female luer lock ports. Our degas modules are suitable for any inkjet printer using compatible inks that requires degassing. It can be operated with one or both vacuum ports. It is an alternative to , and Pall Ultifuzor degasser.

Degassing ink with a membrane prior to it reaching the print head is a simple process. The ink flows on one side of the membrane, while a vacuum is drawn on the other side. Gases dissolved in the ink readily transfer through the membrane to the vacuum side, leaving the ink degassed when it reached the outlet.

For providers of ink in closed loop systems, a membrane degasser is used to degas the ink while filling the vacuum-sealed bags. Because the closed system does not allow air to contact the surface of the ink, as some bulk systems do, the need for additional degassing is minimized. This is especially important for white inks, which must be handled carefully to maintain suspension of the TiO2 pigment. In addition, degassing ink while packaging can reduce foaming, which otherwise will slow the fill process.

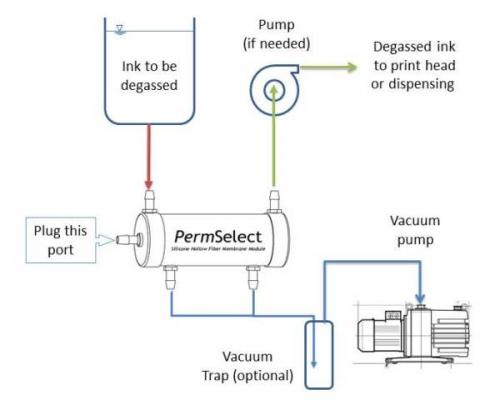

The diagram below depicts a typical ink degassing setup. Note that, if possible, the pump should be placed after the ink degasser to minimize trans-membrane pressure swings, and maintain a more stable pressure differential. Also, it is preferable to place any flow controlling valves upstream from the degasser. A vacuuum trap is optional to protect the vacuum pump in case of a leak develops.

How to Degas Ink:

Degassing ink is simple and straightforward. Simply flow ink through the membrane degasser and apply vacuum to the opposite side of the membrane. Degassed ink exits the degasser. A small diaphragm vacuum pump is typically used as the vacuum source for the printer.