Gas stream dehumidification or gas drying using PermSelect® membrane gas dryers can be accomplished very quickly and easily. Our silicone membrane gas dryers can be used effectively to dehumidify membrane-compatible gas streams in a simple and compact membrane dehumidification system. Because silicone membranes are highly permeable to water vapor they are very efficient in transferring moisture out of gas streams while preserving other gases substantially intact.

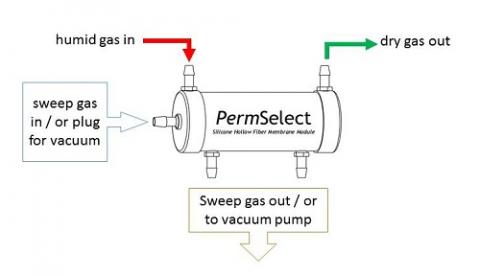

How do I dehumidify my gas stream? Gas stream dehumidification using PermSelect® membrane gas dryers is achieved as illustrated in the figure above where the humid gas stream is supplied to a port at one end cap of the membrane gas dryer. As the humid gas flows through the lumens of the membrane dryer, water vapor is transferred across the membrane driven by the higher partial pressure of the water vapor in the humid gas stream compared to the water vapor pressure outside the hollow fibers (shell side). A non-reactive sweep gas or a vacuum can be used to remove the extracted moisture from the shell side as illustrated below. Alternatively, if the gas is supplied compressed, the extracted moisture can be vented to the atmosphere -if safe.

Warning: To prevent the potential for dangerous reactions, if using a sweep gas, the sweep gas should be inert and not be reactive with the gas to be dehumidified.

There are many advantages to using a PermSelect® membrane dehumidification system to dehumidify your gas stream compared to using conventional gas dehumidification methods such as cold traps and desiccant dehumidifier systems:

- Maintenance-free membrane dehumidification system

- No moving parts compared to refrigerant or regenerating desiccant dehumidifiers

- No CFC gas and no refrigerant needed to dehumidify

- No desiccant needed so there is no need to replace or regenerate desiccants

- Compact and lightweight dehumidification system

- Can passively de-moisturize compressed air by using hollow fiber membranes

- No power source is required and no heat is discharged

- Generates no liquid drain because moisture is removed as vapor

- Easy installation

- Quiet continuous operation

- Environmentally friendly

View a short video demonstrating how to use a PermSelect membrane module to dehumidify your gas stream.

Contact an applications engineer, or call +1 (734) 769-1066 to discuss your particular air/gas dehumidification needs. MedArray provides its PermSelect® membrane modules for gas dehumidification directly to researchers, and to industry through original equipment manufacturers (OEM’s) who are interested in integrating dehumidification solutions in their equipment. We can also customize membrane modules to your specific application. Contact us to discuss your custom application.

Silicone has been used effectively for dehumidification by many researchers. The following list of publications describes using PDMS for dehumidification:

Gayatri Lekshminarayanan, Michelle Croal & Jonathan Maisonneuve (2020) Recovering latent and sensible energy from building exhaust with membrane-based energy recovery ventilation, Science and Technology for the Built Environment, 26:7, 1000-1012, DOI: 10.1080/23744731.2020.1761712

ABSTRACT Energy can be recovered from building exhaust via water vapor transport and heat transfer across gas permeation membranes, thereby reducing latent and sensible loads during both heating and cooling seasons. The process known as membrane-based energy recovery ventilation (ERV) has been commercialized by several HVAC manufacturers, but so far has mostly been offered in flat sheet membrane configurations. In this study, we investigate the use of polydimethyl siloxane membranes packaged into hollow fiber modules, which offer the advantage of high packing density, but which have so far not been commercially adopted due to concerns about parasitic pressure loss. We evaluate here the work required to overcome friction of circulating air through membrane fibers, and we assess the net energy savings that account for these losses relative to the energy saved by water vapor and heat transfer. The concept of normalized net energy savings is introduced to provide a useful metric for comparing performance independent of flow volume and membrane size, and we observe up to 2.75 W/m2 of net latent energy savings. Case studies are used to illustrate the potential of this technology, and energy savings of 1.15 and 1.03 kWh/yr/lpm are demonstrated for Detroit, MI, and Houston, TX, respectively.