Biogas, such as landfill and other anaerobic digester gas, often contains too much CO2 and too low a methane concentration to fuel a natural gas engine for electrical power generation. Typically a 50% methane concentration (minimum heating value (LHV) = 457 Btu/scf) is required for most gas engines to operate properly. PermSelect® silicone membranes can be used to effectively remove CO2 from biogas to a 50% methane concentration or higher if the balance of the biogas composition is primarily CO2. Because CO2 is roughly three times more permeable than methane in silicone, and silicone is a highly permeable membrane material, it is possible to effectively remove CO2 from biogas even at relatively low feed pressures such as 45 psi. The advantage of low pressure CO2 removal is the significant reduction in equipment and operating cost associated with compressing and handling a high pressure flammable gas. Silicone has been shown to be very effective in various methane separations including removal of heavy hydrocarbons (C3+), siloxanes, hydrogen sulfide, water, and other VOC; Indeed, silicone is well known to operate satisfactorily in the field for methane purifications in the presence of combinations of water, carbon dioxide and C3+ hydrocarbons.

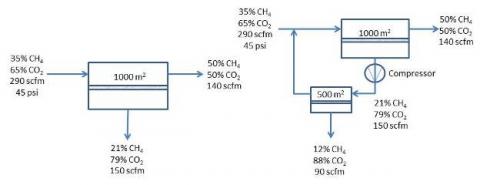

How to Separate CO2 from Landfill Gas? CO2 separation from biogas (landfill gas upgrading) can be performed in a single stage membrane separation, or in two separation stages as illustrated in the figure below. The single stage membrane separation plant is the simplest since there are no moving parts, except for a compressor to pressurize the biogas feed to a pressure of 45 psi. The pressurized feed gas enters the membrane module and drives the CO2 and other contaminants across the membrane (permeate) thus concentrating the methane on the feed side (retentate). The permeate with high concentration of CO2 and low concentration of CH4 can be flared or otherwise disposed properly. The retentate becomes the upgraded biogas which is fed to a gas engine.

In the two stage membrane separation plant, the permeate is re-compressed and directed to a second membrane to further extract CO2, thus reducing overall methane loss. Note that the additional membrane area and additional compressor compared to the single stage membrane separation plant will require additional equipment and higher operating cost.

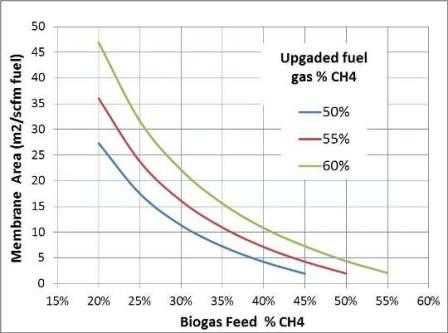

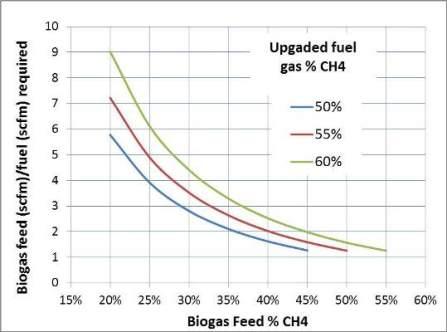

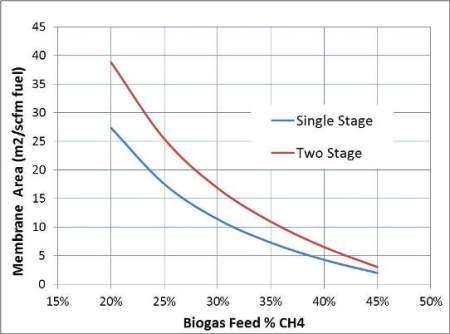

The following graphs present results from simulations of upgrading landfill gas feed concentrations ranging from 20% to 45% methane to a fuel gas concentrations of 50%, 55% and 60% methane suitable for fueling a gas engine. Figure 2 presents the membrane surface area required to accomplish the desired upgraded gas composition and flow as a function of the biogas feed composition.

For example, if the landfill gas composition is 35% methane (65% CO2) and it is desired to upgrade the biogas to 50% methane (50% CO2) to run a gas engine, then from 35% biogas feed (x axis) move vertically to the 50% methane line (blue), then move horizontally to the y axis to find the required membrane area, or 7.2 m2 per scfm fuel required. Thus, if the engine requires 350 scfm of fuel (50% methane) then the membrane area required is 7.2 x 350 = 2,520 m2. Figure 3 presents the required biogas feed flow to provide needed fuel gas flow. In our example above, at 35% feed biogas, the required landfill gas feed is 2.1 times the necessary fuel gas flow or 2.1 x 350 = 735 scfm.

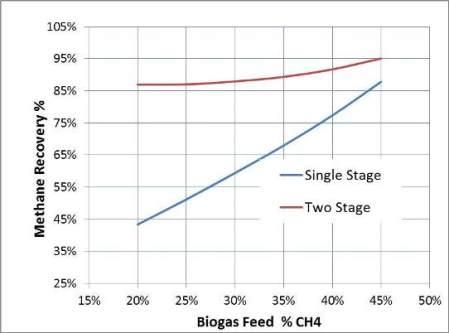

Figures 4 and 5 present a performance comparison between a single stage and two stage membrane separation system for upgrading to a fuel gas methane content of 50%. Note that, as shown in Figure 4, the two stage separation system requires more membrane area for the same level of upgrading; however there is more methane recovery with the two stage system (Figure 5). In other words more of the methane from the biogas feed ends up in the upgraded fuel gas.

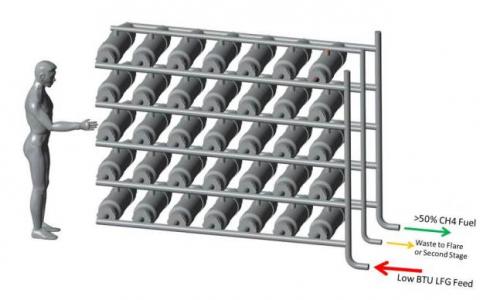

PermSelect manufactures silicone membrane modules for small scale liquid contacting and gas separation applications. Currently, our largest commercial membrane module has 2.1 m2. However, our hollow fiber membrane configuration and module manufacturing process enable effective packaging of large amounts membrane surface area in small volumes, typically greater than 4,000 m2/m3 regardless of module size. Figure 6 illustrates the relative scale of a 3,500 m2 membrane module skid composed of individual 100 m2 modules assembled in parallel to upgrade landfill gas. Based on model simulations, this skid can upgrade landfill gas from 35% to 50% methane and deliver 500 cfm fuel to an IC engine.

Removing siloxanes from biogas (landfill and digester gas). Organo-silicon compounds, known as siloxanes, are found in household and commercial products that are discarded in landfills. Siloxanes find their way into landfill gas, although the amounts vary depending on the waste composition and age. When landfill gas is combusted, siloxanes are converted to silicon dioxide (the primary component of sand). Silicon dioxide is a white substance that collects on the inside of the internal combustion engine and components of the gas turbine, reducing the performance of the equipment and resulting in significantly higher maintenance costs. Removal of siloxane can be both costly and challenging and biogas treatment to remove siloxanes may be required to meet engine manufacturer specifications.

However, with the proposed membrane system, siloxane removal from biogas can be achieved simultaneously with CO2 removal from biogas. Other contaminants such as hydrogen sulfide, heavy hydrocarbons (C3+), and other VOC are also removed from the biogas because their permeability in silicone membrane is higher than the permeability for methane. Thus it is possible to remove siloxanes from biogas in a very simple membrane separation process, which requires low capital and operating costs, compared to adsorption and absorption methods.

We are entertaining inquiries from potential collaborators interested in working with us on acquiring the capability to produce membrane modules with 100 m2 suitable for landfill biogas upgrading. We seek established partners with significant experience in landfill biogas processing including engineering, integrating, and financing. If your organization is interested in collaborating with PermSelect in this endeavor, please contact us or call us at +1 (734) 769-1066 x21 to discuss opportunities.

Silicone has been used effectively for the purification of natural gas commercially and by many researchers. The following list of publications describes using PDMS for purifying biomethane and biohydrogen:

Anaerobic membrane bioreactors (AnMBR) treating urban wastewater in mild climates Bioresource Technology Volume 314, October 2020, 123763, Ángel Robles, et al.

Abstract Feasibility of an AnMBR demonstration plant treating urban wastewater (UWW) at temperatures around 25–30 °C was assessed during a 350-day experimental period. The plant was fed with the effluent from the pre-treatment of a full-scale municipal WWTP, characterized by high COD and sulfate concentrations. Biodegradability of the UWW reached values up to 87%, although a portion of the biodegradable COD was consumed by sulfate reducing organisms. Effluent COD remained below effluent discharge limits, achieving COD removals above 90%. System operation resulted in a reduction of sludge production of 36–58% compared to theoretical aerobic sludge productions. The membranes were operated at gross transmembrane fluxes above 20 LMH maintaining low membrane fouling propensities for more than 250 days without chemical cleaning requirements. Thus, the system resulted in net positive energy productions and GHG emissions around zero. The results obtained confirm the feasibility of UWW treatment in AnMBR under mild and warm climates.

PDMS membranes for feasible recovery of dissolved methane from AnMBR effluents

Journal of Membrane Science, Volume 604, 1 June 2020, 118070, Pau Sanchis-Perucho, et al.

Abstract This study aimed to evaluate the feasibility of degassing membrane (DM) technology for recovering dissolved methane from AnMBR effluents. For that purpose, a PDMS membrane module was operated for treating the effluent from an AnMBR prototype-plant, which treated urban wastewater (UWW) at ambient temperature. Different transmembrane pressures and liquid flow rates were applied for evaluating methane recovery efficiency. Maximum methane recoveries were achieved when increasing the vacuum pressure and reducing the liquid flow rate, reaching a maximum methane recovery efficiency of around 80% at a transmembrane pressure (TMP) of 0.8 bars and a treatment flow rate (QL) of 50 L h−1. The results revealed that the combination of PDMS DMs and AnMBR technology would allow to reduce the energy demand of UWW treatment, achieving net energy productions while reducing greenhouse gas emissions. Optimum operation was determined at a TMP of 0.8 bars and a QL of 150 L h−1 when combining energy, environmental and economic targets. Under these operating conditions, the combination AnMBR + DM resulted in energy requirements and greenhouse gases emissions of −0.040 kWh and 0.113 kg of CO2-eq per m3 of treated water, respectively, resulting in a DM payback period of around 10.5 years.

Biogas purification through membrane bioreactors: Experimental study on siloxane separation and biodegradation Separation and Purification Technology Volume 238, 1 May 2020, 116440, Eric Santos-Clotas et al.

Abstract Sewage biogas valorization to different energy applications is hampered by the presence of volatile methyl siloxanes. Despite the high operating costs, adsorption onto activated carbon is the most implemented technology for siloxane removal from biogas. In order to purify biogas sustainably, the current work explores the diffusion of siloxanes (octamethylcyclotetrasiloxane and decamethylcyclopentasiloxane) together with other biogas impurities (limonene, toluene and hexane) through polydimethylsiloxane membranes. Abiotic tests revealed transport efficiencies above 75% towards a clean air stream for most compounds, although the transport of the most hydrophobic pollutants was challenged when water was circulated through the shell side of the membrane. Moreover, the performance of a hollow-fiber membrane bioreactor, inoculated with anerobic active sludge, was evaluated towards biogas purification in anoxic conditions. Toluene and limonene were successfully degraded, hexane’s removal efficiency was positively correlated with the residence time, and siloxanes removal was achieved up to 21%. CO2 was detected in the outlet gas as the mineralization product as well as some byproducts from the degradation of limonene and siloxanes. The presence of 1% of O2 in the gas, as a strategy to substitute NO3−, efficiently supported high removal for volatile organic compounds and moderate for siloxanes, which would ultimately reduce the operating costs of the technology.

Operational behavior of a hydrogen extractive membrane bioreactor (HEMB) during mixed culture acidogenic fermentation

Abstract Fermentative hydrogen production requires a continuous products-removal and effective upgrading steps to improve its general performance. Therefore, implementation of new technologies capable of achieving both requirements is essential. We present the operational behavior of a new process concept based on integration of membranes for gas separation and fermentation technology. This process, which we term as hydrogen extractive membrane bioreactor consists of coupling two dense polymeric membranes to a hydrogen producing culture. The process automatization of this system was essential to maintain the proper operational pressures in the membrane module and in the bioreactor-gas-phase. This system was able to extract and partially separate the hydrogen and carbon dioxide generated. The hydrogen partial pressure was reduced from 55.5 to 49 KPa, which means an increase of hydrogen yield of 16.3% (1.1–1.28 mol-H2/mol-glucose). Simultaneously, the implemented system generated a final hydrogen stream 13% (v/v) more concentrated than a conventional process.

An integrated system development including PEM fuel cell/biogas purification during acidogenic biohydrogen production from dairy wastewater International Journal of Hydrogen Energy, Volume 44, Issue 32, 28 June 2019, Pages 17297-17303. Emre Oguz Koroglu et al.

Abstract Biohydrogen production from dairy wastewater with subsequent biogas purification by hollow fiber membrane module was investigated in this study. The purified and not purified (raw) biohydrogen were used as fuel in polymer electrolyte membrane (PEM) fuel cell. Furthermore, the effect of CO2 on the performance of PEM fuel cell was evaluated considering cyclic voltammetry (CV), electrochemical impedance spectroscopy (EIS) and polarization curves. The maximum H2 production rate was 0.015 mmol H2/mol glucose and the biohydrogen concentration in biogas was ranged 33%–60% (v/v). CO2/H2 selectivity decreased with increasing pressure and maximum selectivity was obtained as 4.4 at feed pressure of 1.5 bar. The electrochemical active surface (EASA) areas were decreased with increasing CO2 ratio. The maximum power densities were 0.2, 0.08 and 0.045 W cm−2 for 100%, 80% and 60% (v/v) H2, respectively. The results indicated that integrated PEM fuel cell/biogas purification system can be used as a potential clean energy sources during acidogenic biohydrogen production from dairy wastewater.

Improvement of methane content in a hydrogenotrophic anaerobic digester via the proper operation of membrane module integrated into an external-loop Bioresource Technology Volume 245, Part A, December 2017, Pages 1294-1298, Felipe Ojeda et al.

Abstract

This work assessed the feasibility of a hydrogenotrophic biogas process integrated with a membrane module in the external-loop design. The major scope was to conduct the investigation from the perspective of the membrane unit and reveal how the operating strategy influences the efficiency of biogas formation. It was observed that the fermenter worked with an improved efficacy, indicated by the higher concentration of methane in the headspace (80–90%) when the gas loading intensity, defined as the ratio of inlet gas permeation rate and the circulation rate of the liquid phase, was adjusted to lower values (3–5.3 × 10−3). Such results are implying that the mass transfer of H2 into the reactor is dependent on this critical parameter. Moreover, attention should be paid to the fouling of the module under longer-term experiments to keep its performance at a sufficient level.

Performance of polydimethylsiloxane membrane contactor process for selective hydrogen sulfide removal from biogas Waste Management Volume 61, March 2017, Pages 250-257. Tilahun Ebrahim et al.

Abstract H2S in biogas affects the co-generation performance adversely by corroding some critical components within the engine and it has to be removed in order to improve the biogas quality. This work presents the use of polydimethylsiloxane (PDMS) membrane contactor for selective removal of H2S from the biogas. Experiments were carried out to evaluate the effects of different pH of absorption liquid, biogas flowrate and temperature on the absorption performances. The results revealed that at the lowest loading rate (91 mg H2S/m2·h) more than 98% H2S and 59% CO2 absorption efficiencies were achieved. The CH4 content in the treated gas increased from 60 to 80% with nearly 5% CH4 loss. Increasing the pH (7–10) and loading rate (91–355 mg H2S/m2·h) enhanced the H2S absorption capacity, and the maximum H2S/CO2 and H2S/CH4 selectivity factors were 2.5 and 58, respectively. Temperature played a key role in the process and lower temperature was beneficial for intensifying H2S absorption performance. The highest H2S fluxes at pH 10 and 7 were 3.4 g/m2·d and 1.8 g/m2·d with overall mass transfer coefficients of 6.91 × 10−6 and 4.99 × 10−6 m/s, respectively. The results showed that moderately high H2S fluxes with low CH4 loss may be achieved by using a robust and cost-effective membrane based absorption process for desulfurization of biogas. A tubular PDMS membrane contactor was tested for the first time to remove H2S from biogas under slightly alkaline conditions and the suggested process could be a promising for real scale applications.

- LOW PRESSURE SEPARATION TECHNIQUE OF BIOGAS INTO CH4 AND CO2 EMPLOYING PDMS MEMBRANE International Journal of Advanced Engineering Technology Vol.III/ Issue I/January-March, 2012/311-315 Swanand Kalambe et al.

-

Abstract Continuous research has been going on to find out easy and cheap technique for separation of biogas employing membrane technology. Work has been carried out to find the best suited membrane for gas separation with low operational pressure and cost. Membrane gas separation technique is very advantageous as it doesn’t require huge infrastructure for plant set up due to low pressure requirement for the process and availability of membrane at a reasonable cost. This technique has generated immense commercial interest. This paper deals with an advanced separation technique employing poly dimethylsiloxane (PDMS) hollow fiber membrane module. The results clearly show that, PDMS double membrane module in series gave the upgraded methane with 93 % purity and carbon dioxide with 96% purity.

Evaluation of two gas membrane modules for fermentative hydrogen separation International Journal of Hydrogen Energy Volume 38, Issue 32, 25 October 2013, Pages 14042–14052 J.E. Ramírez-Morales et al.

Abstract The ability of (dimethyl siloxane) (PDMS) and SAPO 34 membrane modules to separate a H2/CO2 gas mixture was investigated in a continuous permeation system in order to decide if they were suitable to be coupled to a biological hydrogen production process. Permeation studies were carried out at relatively low feed pressures ranging from 110 to 180 kPa. The separation ability of SAPO 34 membrane module appeared to be overestimated since the effect concentration polarization phenomena was not taken into consideration in the permeation parameter estimation. On the other hand, the PDMS membrane was the most suitable to separate the binary gas mixture. This membrane reached a maximum CO2/H2 separation selectivity of 6.1 at 120 kPa of feed pressure. The pressure dependence of CO2 and H2 permeability was not considerable and only an apparent slight decrease was observed for CO2 and H2. The mean values of permeability coefficients for CO2 and H2 were 3285 ± 160 and 569 ± 65 Barrer, respectively. The operational feed pressure found to be more adequate to operate initially the PDMS membrane module coupled to the fermentation system was 180 kPa, at 296 K. In these conditions it was possible to achieve an acceptable CO2/H2 separation selectivity of 5.8 and a sufficient recovery of the CO2 in the permeate stream.

Siloxane removal using silicone–rubber membranes Separation and Purification Technology, Volume 89, 22 March 2012, Pages 234–244 Marc Ajhar et al.

Abstract Landfill and digester gas purification processes usually incorporate the removal of volatile methylsiloxanes (VMS). State-of-the-art technology is adsorption on activated carbon. This paper investigates a potential alternative: membranes. The permeabilities of common VMS in a commercially available polydimethylsiloxane (PDMS) membrane are determined as a function of temperature. A synthetic biogas mixture containing silicon in landfill gas-typical concentrations is purified in 3-end and 4-end operation. The results are presented using dimensionless numbers to facilitate upscaling. In general, PDMS can be used for siloxane removal, especially in 4-end operation using ambient air as sweep gas, where energy demand is significantly lower than in 3-end. However, depending on the desired degree of purification, methane losses of approximately 7% must be accepted. Only alternative membrane materials with higher carbon dioxide–methane selectivities have the potential for lower methane losses.